Channel fittings are used with channel tray, which is used in industrial plants to route instrument tubing or electrical or data/communications cable. Channel fittings are the connecting pieces that provide smooth and easy transitions between components and channel cable tray. Channel fittings are manufactured by welding together various components that are precisely cut by a CNC plasma cutter to form the fitting that is desired. There are several types of channel fittings including channel splice, which connects end-to-end channel tray, vertical outside bends, vertical outside elbows, vertical inside elbows, horizontal elbows, radius tees, radius crosses, and more. These all connect channel cable trays for routing cable from different planes.

In addition to standard channel fittings, TechLine Mfg. provides unique fittings that provide added value to our customers by reducing field labor. With fittings that are available already made, customers use TechLine Mfg. fittings rather than fabricating them in the field, which saves more time and labor.

Industries for Channel Fittings

Some common industries for channel fittings include:

- Oil & Gas

- Power

- Pulp & Paper

- Refineries

- Chemical plants

- LNG plants

- Power generating facilities

Channel Fitting Materials

TechLine Mfg. offers channel fittings in Aluminum, 304 and 316 stainless steel, and hot dipped galvanized carbon steel. Several factors when choosing a material for channel fittings include climate, holding weight, stain and corrosion resistance, cutting abilities, and material costs.

| Material | Benefits |

| Aluminum |

Lighter/cost effective option |

| Galvanized Steel |

More rigid/ heavier option |

| Stainless Steel |

Highest tolerance from rust/corrosion |

Strength & Protection:

Solid bottom & side rails

for maximum strength & protection

UL Classified:

TechLine Mfg. Channel products are available in UL Classified. File number

E249472. Please specify upon request for UL Classification labels.

Click here to view All Channel Fittings Cut Sheets

_ _ indicates material choice; AL, SS, 6SS, HDG

| Channel Splice | |||

| TLCS-2-1-AL | 2” | 1” | 1 LBS |

| TLCS-2-1-HDG | 2” | 1” | 2 LBS |

| TLCS-2-1-SS | 2” | 1” | 1 LBS |

| TLCS-2-2-AL | 2” | 2” | 1 LBS |

| TLCS-2-2-HDG | 2” | 2” | 2 LBS |

| TLCS-2-2-SS | 2” | 2” | 1 LBS |

| TLCS-4-1-AL | 4” | 1" | 1 LBS |

| TLCS-4-1-HDG | 4” | 1” | 2 LBS |

| TLCS-4-1-SS | 4” | 1” | 1 LBS |

| TLCS-4-2-AL | 4” | 2” | 1 LBS |

| TLCS-4-2-HDG | 4” | 2” | 3 LBS |

| TLCS-4-2-SS | 4” | 2” | 2 LBS |

| TLCS-6-1-AL | 6” | 1” | 1 LBS |

| TLCS-6-1-HDG | 6” | 1” | 3 LBS |

| TLCS-6-1-SS | 6” | 1” | 2 LBS |

| TLCS-6-2-AL | 6” | 2” | 2 LBS |

| TLCS-6-2-HDG | 6” | 2” | 3 LBS |

| TLCS-6-2-SS | 6” | 2” | 2 LBS |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 90° Vertical Outside Bend 3” Radius |

|||

| TLVO-2-1- __ __3R | 2” | 1” | 8.5” |

| TLVO-2-2- __ __3R | 2” | 2” | 8.5” |

| TLVO-4-1- __ __3R | 4” | 1” | 8.5” |

| TLVO-4-2- __ __3R | 4” | 2” | 8.5” |

| TLVO-6-1- __ __3R | 6” | 1” | 8.5” |

| TLVO-6-2- __ __3R | 6” | 2" | 8.5” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 90° Vertical Inside Bend 3” Radius |

|||

| TLVI-2-1- __ __3R | 2” | 1” | 7.5” |

| TLVI-2-2- __ __3R | 2” | 2” | 7.5” |

| TLVI-4-1- __ __3R | 4” | 1” | 7.5” |

| TLVI-4-2- __ __3R | 4” | 2” | 7.5” |

| TLVI-6-1- __ __3R | 6” | 1” | 7.5” |

| TLVI-6-2- __ __3R | 6” | 2” | 7.5” |

_ _ indicates material choice; AL, SS, 6SS, HDG

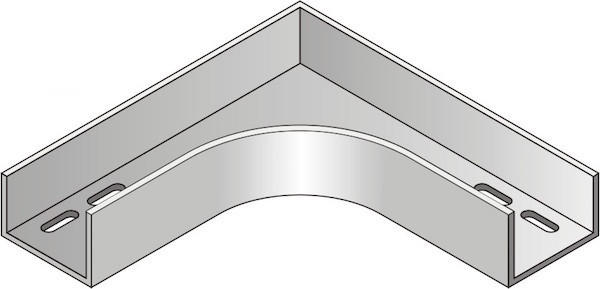

| 90° Horizontal Elbow 3” Radius |

|||

| TLHE-2-1- __ __3R | 2” | 1” | 8.5” |

| TLHE-2-2- __ __3R | 2” | 2” | 7.5” |

| TLHE-4-1- __ __3R | 4” | 1” | 7.5” |

| TLHE-4-2- __ __3R | 4” | 2” | 7.5” |

| TLHE-6-1- __ __3R | 6” | 1” | 7.5” |

| TLHE-6-2- __ __3R | 6” | 2" | 7.5” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 90° Vertical Outside Elbow 12” Radius |

|||

| TLVO-2-1- __ __ 12R | 2” | 1” | 21” |

| TLVO-2-2- __ __12R | 2” | 2” | 21” |

| TLVO-4-1- __ __12R | 4” | 1” | 23” |

| TLVO-4-2- __ __12R | 4” | 2” | 23” |

| TLVO-6-1- __ __12R | 6” | 1” | 25” |

| TLVO-6-2- __ __12R | 6” | 2" | 25” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 90° Vertical Inside Elbow 14” Radius |

|||

| TLVI-2-1- __ __14R | 2” | 1” | 21” |

| TTLVI-2-2- __ __14R | 2” | 2” | 21” |

| TLVI-4-1- __ __14R | 4” | 1” | 23” |

| TLVI-4-2- __ __14R | 4” | 2” | 23” |

| TLVI-6-1- __ __14R | 6” | 1” | 25” |

| TLVI-6-2- __ __14R | 6” | 2" | 25” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 90° Horizontal Outside Elbow 12” Radius |

|||

| TLHE-2-1- __ __12R | 2” | 1” | 19” |

| TLHE-2-2- __ __12R | 2” | 2” | 19” |

| TLHE-4-1- __ __12R | 4” | 1” | 21” |

| TLHE-4-2- __ __12R | 4” | 2” | 21” |

| TLHE-6-1- __ __12R | 6” | 1” | 23” |

| TLHE-6-2- __ __12R | 6” | 2" | 23” |

_ _ indicates material choice; AL, SS, 6SS, HDG

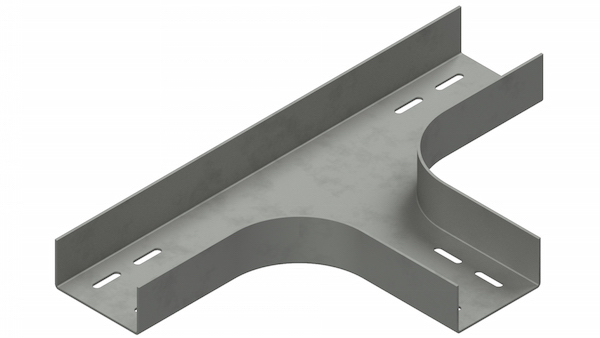

| 3” Radius Tee | ||||

| TLCT-2-1- __ __ 12R | 2” | 1” | 17.25” | 9.5” |

| TLCT-2-2- __ __ 3R | 2” | 2” | 17.25” | 9.5” |

| TLCT-4-1- __ __ 3R | 4” | 1” | 19.25” | 11.5” |

| TLCT-4-2- __ __ 3R | 4” | 2” | 19.25” | 11.5” |

| TLCT-6-1- __ __ 3R | 6” | 1” | 21.25” | 13.5” |

| TLCT-6-2- __ __ 3R | 6” | 2” | 21.25” | 13.5” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 12” Radius Tee | ||||

| TLCT-2-1- __ __ 12R | 2” | 1” | 35” | 18” |

| TLCT-2-2- __ __ 3R | 2” | 2” | 35” | 18” |

| TLCT-4-1- __ __ 3R | 4” | 1” | 37” | 20” |

| TLCT-4-2- __ __ 3R | 4” | 2” | 37” | 20” |

| TLCT-6-1- __ __ 3R | 6” | 1” | 39” | 22” |

| TLCT-6-2- __ __ 3R | 6” | 2” | 39” | 22” |

_ _ indicates material choice; AL, SS, 6SS, HDG

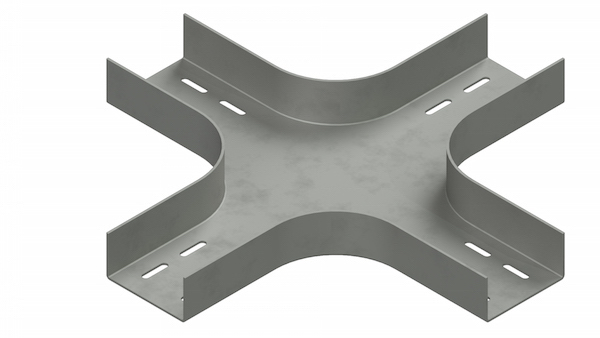

| 3” Radius Cross | ||||

| TLCC-2-1- __ __ 3R | 2” | 1” | 17.25” | 17.25” |

| TLCC-2-2- __ __ 3R | 2” | 2” | 17.25” | 17.25” |

| TLCC-4-1- __ __ 3R | 4” | 1” | 19.25” | 19.25” |

| TLCC-4-2- __ __ 3R | 4” | 2” | 19.25” | 19.25” |

| TLCC-6-1- __ __ 3R | 6” | 1” | 21.25” | 21.25” |

| TLCC-6-2- __ __ 3R | 6” | 2” | 21.25” | 21.25” |

_ _ indicates material choice; AL, SS, 6SS, HDG

| 12” Radius Cross | ||||

| TLCC-2-1- __ __ 12R | 2” | 1” | 35” | 35” |

| TLCC-2-2- __ __ 12R | 2” | 2” | 35” | 35” |

| TLCC-4-1- __ __ 12R | 4” | 1” | 37” | 37” |

| TLCC-4-2- __ __ 12R | 4” | 2” | 37” | 37” |

| TLCC-6-1- __ __ 12R | 6” | 1” | 39” | 39” |

| TLCC-6-2- __ __ 12R | 6” | 2” | 39” | 39” |