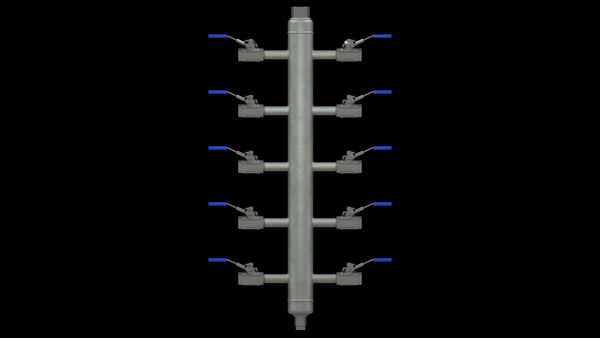

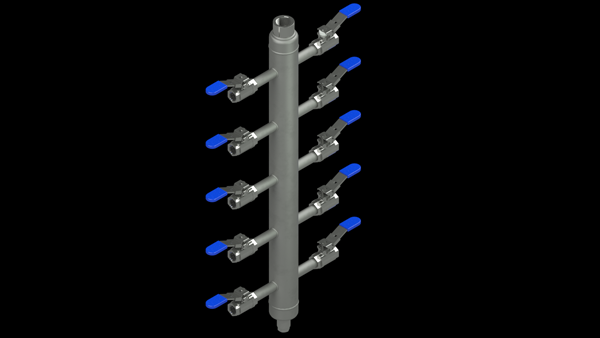

Air distribution manifolds, also known as air and steam header manifolds, are used to divert a single gas, air, or liquid feed line to multiple locations or devices. Instrument air manifolds are also used to evacuate unwanted fluid or condensation from the vent valve before it gets to the operating machinery and causes corrosion. Air distribution manifolds allow for multiple connection options for isolation.

Air distribution manifolds, also known as air and steam header manifolds, are used to divert a single gas, air, or liquid feed line to multiple locations or devices. Instrument air manifolds are also used to evacuate unwanted fluid or condensation from the vent valve before it gets to the operating machinery and causes corrosion. Air distribution manifolds allow for multiple connection options for isolation.

Contact us to build air distribution manifolds to your drawings or specifications.

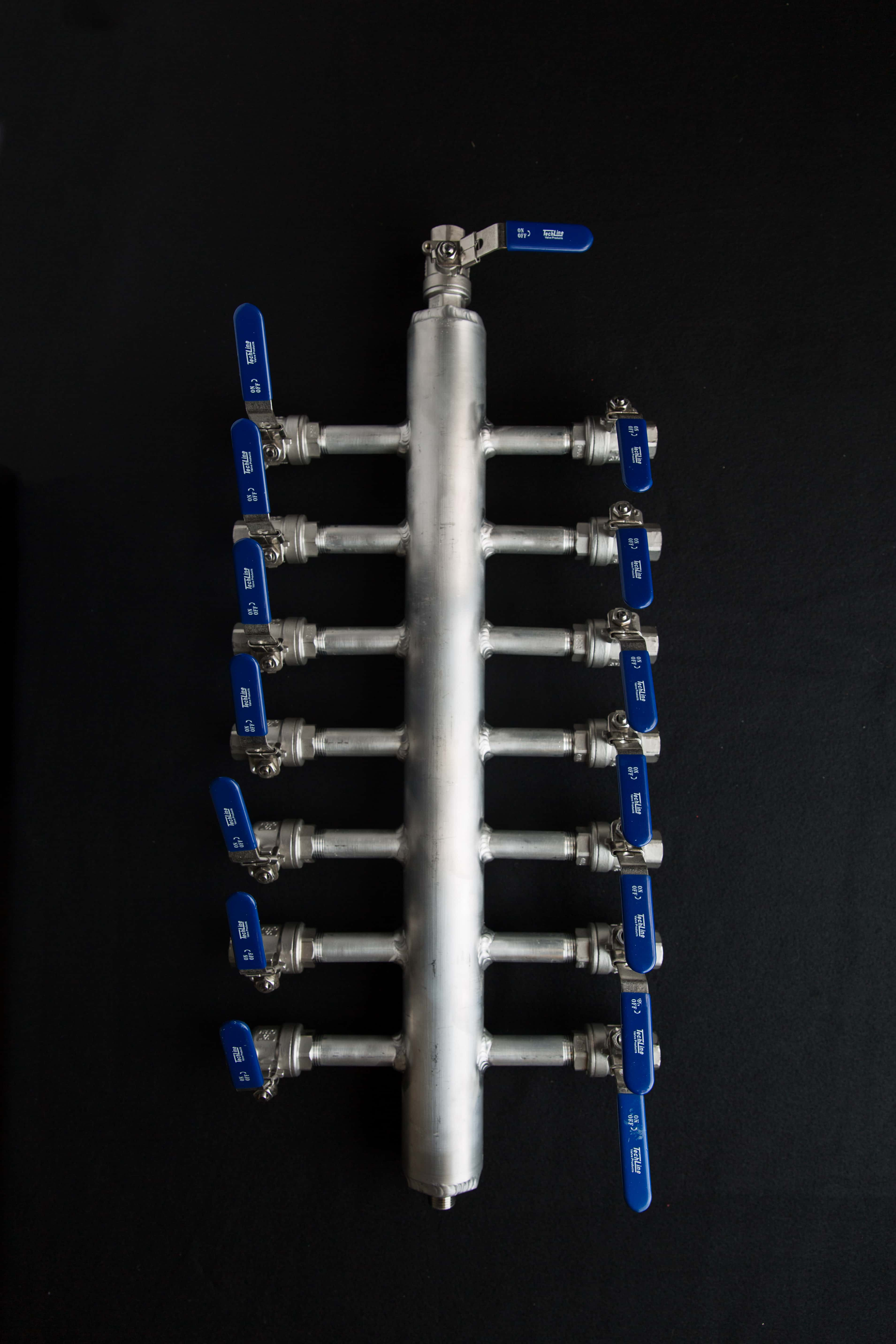

Air Distribution Manifold Manufacturing Process

TechLine Mfg.’s Engineering Department works with our customers to build each air header manifold to the exact requirements needed. Each steam header manifold is welded to exact specifications described on the production drawing developed. The body is made from welded s/40 pipe, and the ports can be a male or female orientation in the size of choice. Male ports are 3” long threaded pipe nipples, and female connections are usually half- couplings welded to the body. On the ends we offer the option of a male, female, socket weld, or 150# raised face flanged inlet, and threaded, capped, or vent valve on the other end allowing condensation to exit the system. Ball valves and vent valves are also available from TechLine Mfg. to consolidate purchasing and assembly process to save time.

Air Distribution Manifold Applications

These instrument air manifolds are utilized at any type of plant, warehouse, machine shop, and other facility where a large compressor supplies multiple fixed-air supply lines to secondary uses of the compressed air.

Instrument Air Manifold Materials

The most common materials used for air header manifolds are stainless steel and carbon steel. Stainless steel is the strongest and longest lasting material we can use, while carbon steel is the most cost-effective. We do not advise using aluminum for steam header manifolds due to its weak nature. Aluminum, 304SS, and 316SS materials available upon request.

Pressure Testing for Air Distribution Manifolds

All TechLine Mfg. air distribution manifolds are pressure tested to the customer specification prior to shipment. Pressure testing allows us to look over the entire instrument air manifold to ensure there are no leaks in the welds, valves, and connection threads. Upon request, any air header manifold can be further tested by having all welds X-ray tested and dye-penetrant tested. This completely checks the welds for full penetration unions.

Our steam header manifolds are available in various pipe sizes, schedules and lengths, the distance between taps may vary depending upon customer specifications. Standard dimensions are 5” apart. Connections are available in threaded, socket weld or flanged.

Two piece 1/2’ threaded TechLine ball valves and 1/2” bleed valve.